The Challenge: Engineering for a Road Less Traveled

Conventional vehicle designs, optimized for developed markets, fail to address the realities of rural Nepal. The core challenge was to design a vehicle platform from the ground up that could withstand severe terrain, meet stringent economic constraints, and overcome limited infrastructure. The project's goal was to create a solution that was not just functional, but also sustainable and empowering for the local communities.

I focused on a space frame chassis architecture—a robust, skeletal frame—as a strategic alternative to a unibody design. This approach eliminates the need for expensive factory tooling, enabling decentralized, local manufacturing and making repairs significantly easier and cheaper.

My Role: Lead Design & Simulation Engineer

As the sole engineer on this project, I managed the entire design and validation lifecycle, from conceptualization to final analysis. My responsibilities were comprehensive and technically focused:

- System Architecture Design: Led the decision-making process to select the space frame architecture over alternatives, based on a rigorous analysis of project constraints like cost, manufacturability, and repairability.

- Parametric CAD Modeling: Developed a high-fidelity 3D model of the chassis in SolidWorks 2023 R1, incorporating Design for Manufacture and Assembly (DFMA) principles to ensure it could be built with local tooling.

- Finite Element Analysis (FEA): Conducted a multi-physics simulation suite in ANSYS to virtually validate the design's real-world performance under extreme conditions.

- Data Analysis & Interpretation: Processed and interpreted simulation results to quantify the design's performance against key engineering metrics for safety, durability, and structural integrity.

Simulation Analysis & Key Findings

To validate the design without costly physical prototypes, I performed three critical virtual tests. Each simulation provided crucial data on the chassis's fitness for its demanding operational environment. Click on any image to view a larger version.

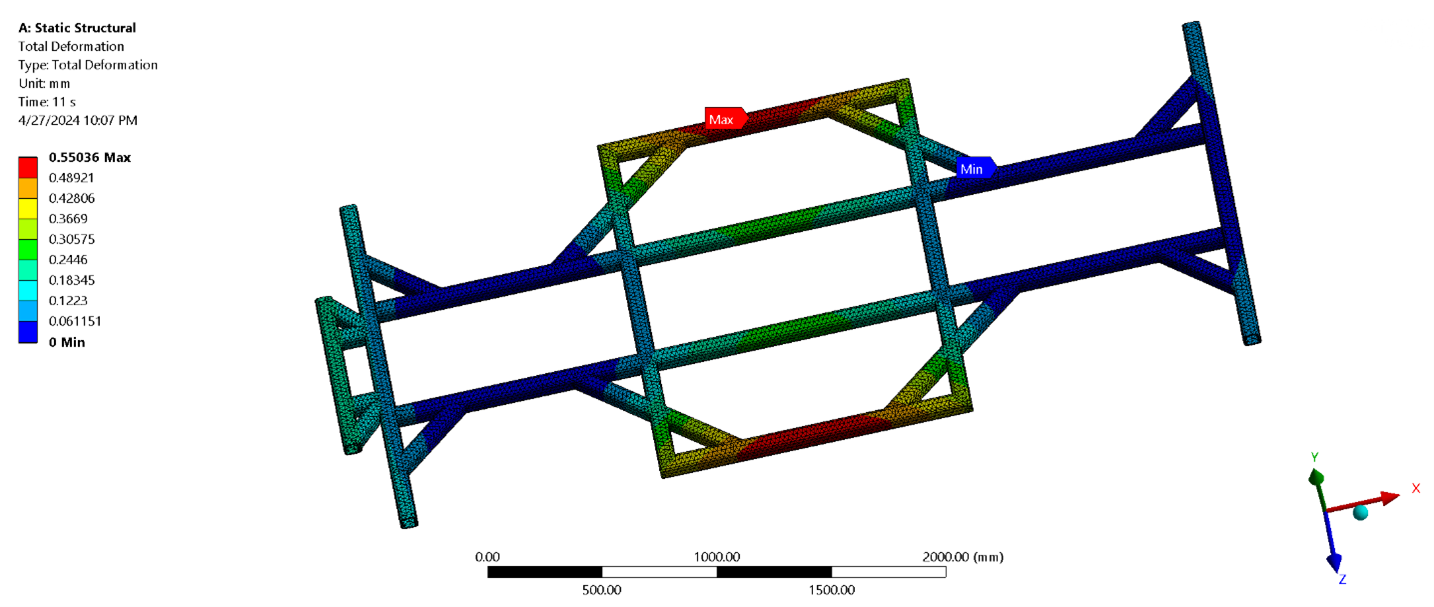

1. Static Structural Analysis (Max Payload Test)

This test simulated the stress on the chassis when fully loaded with 2000 kg (4,400 lbs). The result was exceptional: the maximum stress was only 41.14 MPa, far below the steel's failure point, and the frame deflected by a mere 0.55 mm, confirming its immense stiffness and strength.

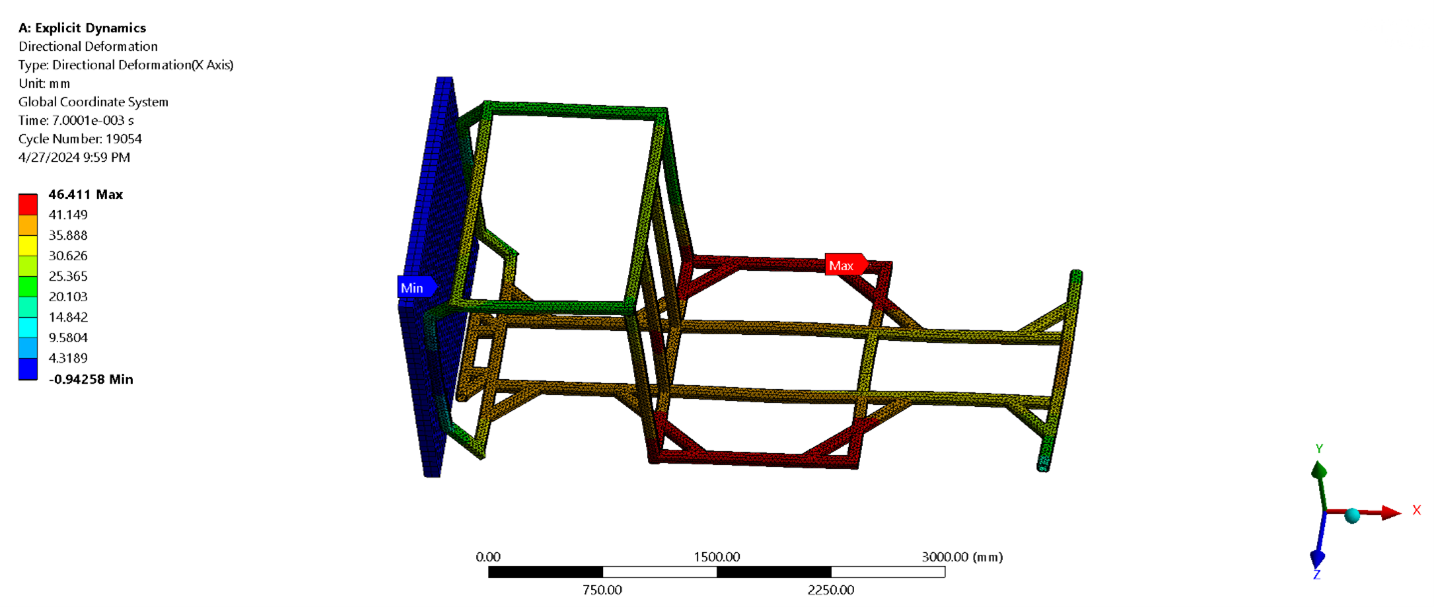

2. Explicit Dynamics (50 mph Crash Test)

To ensure occupant safety, I simulated a severe 50 mph frontal collision. The chassis performed exactly as designed, with the front-end crumpling to absorb impact energy while preserving the integrity of the passenger cell. The total deformation was a controlled 46.41 mm.

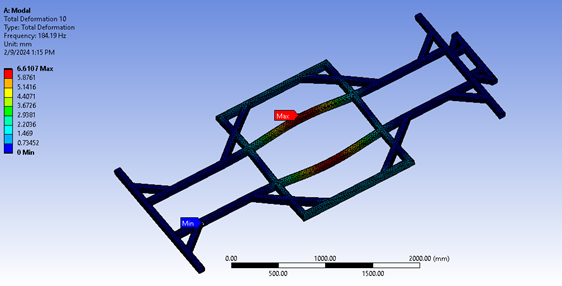

3. Modal Analysis (Rough Road Durability Test)

This analysis identified the chassis's natural vibration frequencies to prevent dangerous resonance. Fatigue analysis predicted a virtually infinite life cycle (over 1 million cycles), proving the design can withstand a lifetime of use on rough roads without cracking.

Conclusion & Project Impact

The comprehensive simulation and analysis process successfully validated the modular space frame chassis as a robust, safe, and viable solution for rural transportation. The data-driven approach confirmed that the design meets all core engineering objectives.

- Structurally Superior: The chassis exhibits excellent stiffness and strength, with a minimum safety factor of 2.09, ensuring reliability under extreme payloads.

- Inherently Safe: The design provides predictable and controlled energy absorption during a collision, prioritizing occupant protection.

- Built for Durability: An infinite predicted fatigue life ensures the vehicle can withstand the cumulative stress of harsh rural roads for years to come.

- Economically Viable: The design is optimized for low-cost, decentralized manufacturing, making it an accessible and sustainable solution for its target communities.

Ultimately, this project provides a validated engineering blueprint for a vehicle that can do more than just navigate tough terrain; it can foster local industry, improve accessibility, and create a more sustainable transportation ecosystem.